About Batch Bottom Drive Homogeniser

1. Batch Homogenizers:

1.1. Batch Type In tank Homogenizer:

Wahal portable batch type in tank mixer is highly useful for batch preparation. The in tank homogenizers comprises of a single set of working head, i.e., a rotor-stator where the centrifugal forces created by the rotor sucks the material in the working heads and throwing it outwards to the stator walls, where the shearing takes place ensuring highly narrow and efficient droplet size distribution and evenly dissolved solids. Hence it becomes impossible for the material to miss from passing from the inlet to the outlet without being subjected mechanical shear action. The stator is available with perforations of different size and shapes. This gives the advantage to the machine to adopt different processing operations.

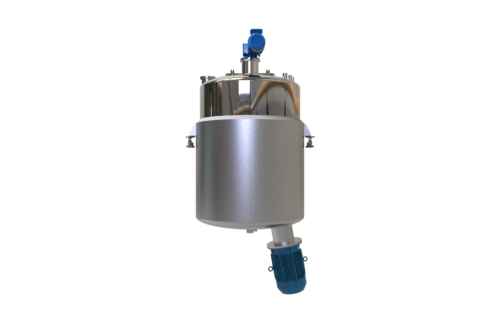

1.2. Bottom Mounted Batch Homogenizer:

The bottom mounted homogenizers are best suitable for dis-integrating, dissolving, solubilizing, and dispersing solid in the liquids and can accommodate harder solids into the liquids/solutions as desired by the application.

The bottom drive is mounted on the bottom of the vessel with the working head (rotor & stator) dipping in the material being processed. The homogenizer is responsible for dis-integrating solids in the liquid and break huge blocks/bricks/agglomerates present into fine particles to ease the dissolving of the solids in the liquids. The solids are literally ripped apart into fine particles and are easily dispersed into the mix.