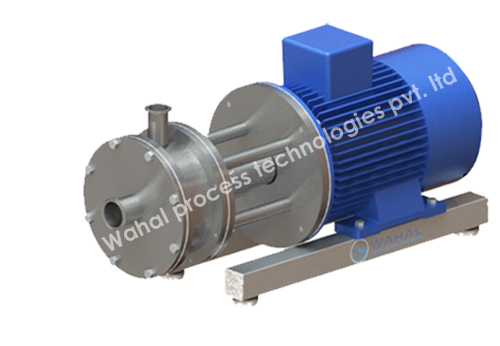

In-Tank Homogenizer

In-Tank Homogenizer Specification

- Type

- Homogenizer

- Material

- Stainless Steel

- Control Mode

- Semi-Automatic

- Voltage

- 220-240 Volt (v)

- Weight (kg)

- 20 Kilograms (kg)

In-Tank Homogenizer Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Days

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Western Europe, Middle East, Central America, Eastern Europe, Africa, South America, Australia, Asia, North America

- Main Domestic Market

- All India

About In-Tank Homogenizer

1. BatchHomogenizers:

1.1.Batch Type In tank Homogenizer:

Wahal portable batch type in tank mixer is highly useful forbatch preparation. The in tank homogenizers comprises of a single set ofworking head, i.e., a rotor-stator where the centrifugal forces created by therotor sucks the material in the working heads and throwing it outwards to thestator walls, where the shearing takes place ensuring highly narrow andefficient droplet size distribution and evenly dissolved solids. Hence itbecomes impossible for the material to miss from passing from the inlet to theoutlet without being subjected mechanical shear action. The stator is availablewith perforations of different size and shapes. This gives the advantage to themachine to adopt different processing operations.

1.2. Bottom Mounted BatchHomogenizer:

The bottom mounted homogenizers arebest suitable for dis-integrating, dissolving, solubilizing, and dispersingsolid in the liquids and can accommodate harder solids into theliquids/solutions as desired by the application.

The bottom drive is mounted on thebottom of the vessel with the working head (rotor & stator) dipping in thematerial being processed. The homogenizer is responsible for dis-integratingsolids in the liquid and break huge blocks/bricks/agglomerates present intofine particles to ease the dissolving of the solids in the liquids. The solidsare literally ripped apart into fine particles and are easily dispersed intothe mix.

1.1.Batch Type In tank Homogenizer:

Wahal portable batch type in tank mixer is highly useful forbatch preparation. The in tank homogenizers comprises of a single set ofworking head, i.e., a rotor-stator where the centrifugal forces created by therotor sucks the material in the working heads and throwing it outwards to thestator walls, where the shearing takes place ensuring highly narrow andefficient droplet size distribution and evenly dissolved solids. Hence itbecomes impossible for the material to miss from passing from the inlet to theoutlet without being subjected mechanical shear action. The stator is availablewith perforations of different size and shapes. This gives the advantage to themachine to adopt different processing operations.

1.2. Bottom Mounted BatchHomogenizer:

The bottom mounted homogenizers arebest suitable for dis-integrating, dissolving, solubilizing, and dispersingsolid in the liquids and can accommodate harder solids into theliquids/solutions as desired by the application.

The bottom drive is mounted on thebottom of the vessel with the working head (rotor & stator) dipping in thematerial being processed. The homogenizer is responsible for dis-integratingsolids in the liquid and break huge blocks/bricks/agglomerates present intofine particles to ease the dissolving of the solids in the liquids. The solidsare literally ripped apart into fine particles and are easily dispersed intothe mix.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Homogenizers Category

In-Tank Homogeniser

Price 25000 INR

Minimum Order Quantity : 1 Unit

Type : Other, Homogeniser

Voltage : 220240 Volt (v)

Color : Silver

Material : Stainless Steel

In-Line Homogeniser

Price 25000 INR

Minimum Order Quantity : 1 Unit

Type : Other, Homogeniser

Voltage : 400440 Volt (v)

Color : Silver

Material : Stainless Steel

|

WAHAL PROCESS TECHNOLOGIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry